Field Testing

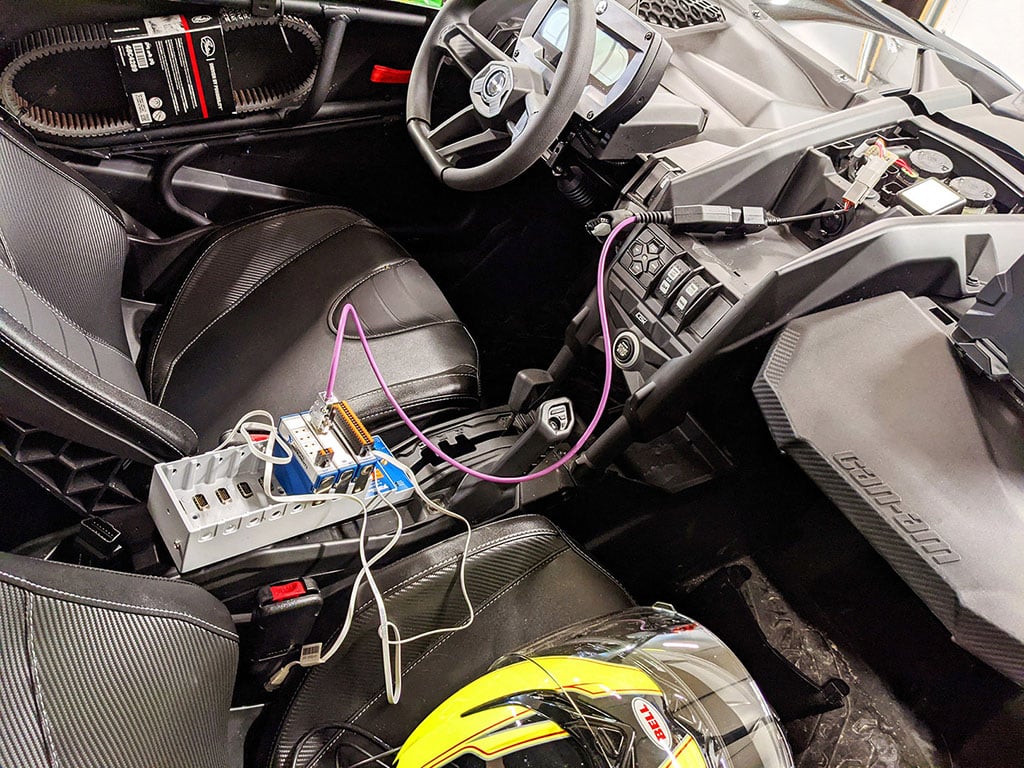

Key individuals involved in the development and design of a product, take that product to the field and put it through its paces. In an ideal world, this testing is performed to test actual field conditions on prototype or production components and designs.

Field testing is important because it demonstrates how a product reacts to real field inputs that cannot be replicated in the theoretical design stage. It assures that the product lives up to expectations when put to the test. Finally, it allows designers and engineers to improve and adapt the product based on the information gathered during testing.

DYOT can help take your field testing to the next level. With over a decade of test experience, we work with you to help determine what inputs are important to your design and show you how to gather real, precise actionable data from your products in the field.

New Product Development

New product development is the process a company goes through to create or improve a new product, keeping it on pace with the market. It allows you to benchmark to your competitors or to introduce a new improved design all together.

DYOT can assist your team in learning about your product through data and analysis. We help you truly understand how your design stacks up against others in the same space, what sets you apart, and where you can improve.

Industrial Testing

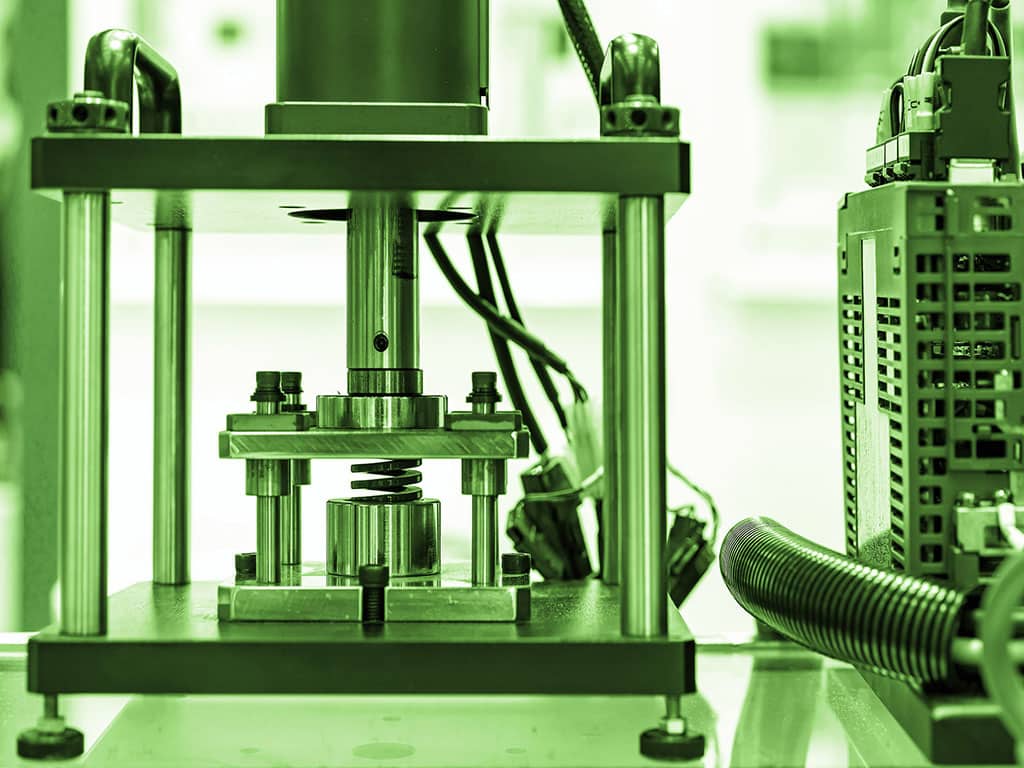

Industrial testing (in-house testing) takes the results from field testing and/or the new product development process and creates test machines that can replicate field results and failures.

It allows you to assess the data acquired from field testing and customer feedback to develop in-house testing of component-level parts, or to replicate whole field scenarios. This process can significantly reduce development time by eliminating the guesswork.

DYOT can guide you through the process of incorporating the machines you need in your arsenal to test important components rapidly and repeatably.